In der Industrie 4.0 kommen Backroboter zur Produktion von Backwaren zum Einsatz. Wie wir mit unserer Montage für volle Schultüten sorgen, hier erfahren!

Basicsphere: A Comprehensive Guide to our 7 Phases of Machine Relocation

A successful machine relocation requires careful planning and precise execution to minimize downtime and ensure safety. The good news is that the process can be divided into seven essential phases. With our services, we assist you with your machine relocation, so you stay on top of everything!

1. Planning: Establishing a clear roadmap for the relocation of your machines:

The initial stage of the process entails an assessment to ascertain the extent and specifications of the machine relocation. This is followed by comprehensive project planning, during which schedules, resources, and responsibilities are defined. It is essential to conduct meticulous planning to ensure seamless coordination of all aspects of the relocation and to mitigate potential risks.

2. Preparing: Ensuring that all prerequisites are met for a smooth relocation:

During this phase of the machine relocation, all necessary documentation is created, and the disassembly of the machines is carefully planned. We ensure that all parts are properly packed and protected to avoid damage during transport. Additionally, all components must be clearly labeled to ensure a smooth reassembly at the new location.

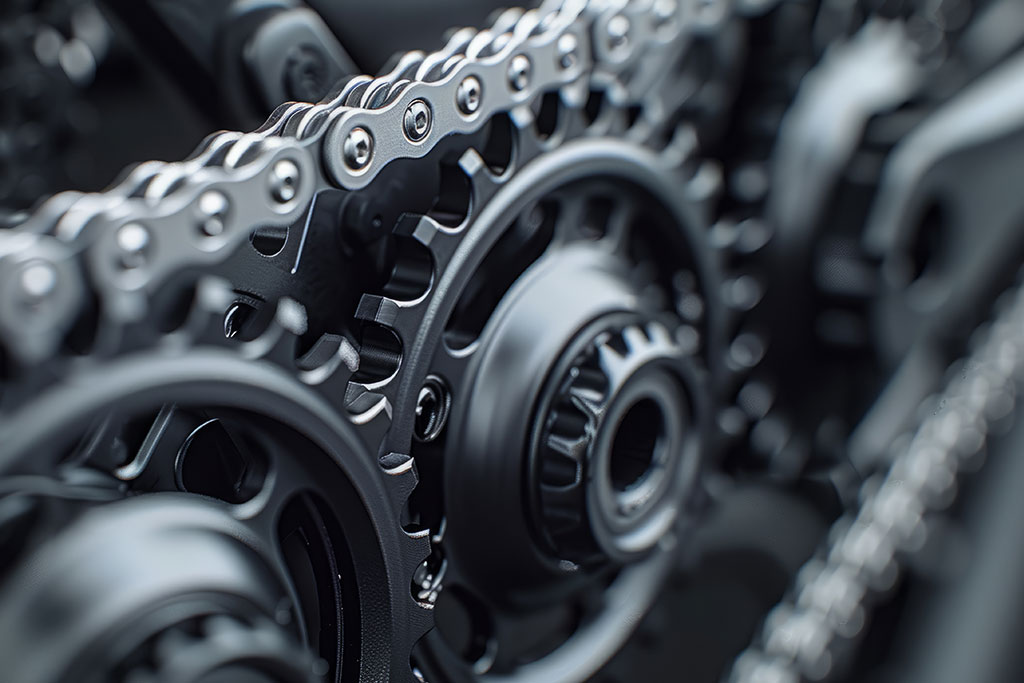

3. Disassembly: We safely disassemble your machines for transport:

Safety is our top priority during machine relocation. We implement comprehensive safety measures before the actual disassembly begins. After disassembly, we inspect each part to ensure there are no damages or defects. This allows us to properly reassemble the machines at the new location.

4. Transport: Security goes first while relocating your machines:

In the fourth step, the transport of the machines is organized. The most appropriate transportation methods are selected, and a detailed logistics plan is put in place. The machines are loaded carefully to prevent damage, and the actual transport is monitored to ensure everything goes according to plan during the machine relocation.

5. Assembly: We reassemble your machines at the new location:

Once the machines have been transported to the new location, our experts will unload them and reassemble them. We use state-of-the-art assembly equipment to ensure that all connections are made correctly and that the machines are fine-tuned to guarantee their proper functioning.

6. Commissioning: Testing and validating the machinery to ensure it operates correctly:

Following assembly, test runs are conducted to verify the proper functioning of the machines following the relocation. Additionally, employees are trained to operate the new or relocated machines safely and efficiently. All relevant documentation is updated accordingly.

7. Evaluation and control:

As the final phase of our machine relocation service, we conduct a comprehensive evaluation of the entire relocation process. This post-check ensures that all machines are functioning optimally and that all relocation objectives have been met.

In the realm of machine relocation, we are your reliable and competent partner. We are here to address any questions you may have about our services—feel free to reach out to us directly!